News

30 2025-09

30 2025-09 What are the industry standards for ground spur pinion shafts?

Industry standards for ground spur pinion shafts define precise specifications for geometry, materials, and surface finish to ensure durability, efficiency, and reliability in power transmission systems.

29 2025-09

29 2025-09 Can Ground Spur Gears Be Customized for Specific Needs?

Ground spur gears can be fully customized to meet specific requirements in design, material, and performance. This flexibility ensures they are suitable for various industrial applications.

26 2025-09

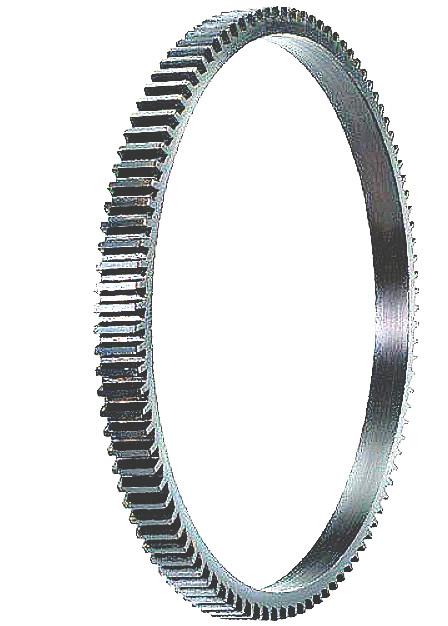

26 2025-09 What are the noise and vibration characteristics of steel ring gears (spur gears)?

Steel spur gears produce moderate noise and vibration due to their straight-tooth design, which causes sudden tooth engagement. Factors like manufacturing precision, load, and lubrication significantly influence their acoustic and dynamic performance.

25 2025-09

25 2025-09 What are the main differences between spur pinion shafts and helical pinion shafts?

The main difference between helical gear shafts and spur gear shafts lies in the tooth design: the spur gear shaft has a tooth profile parallel to the axis and is suitable for low-speed and low-load scenarios; the helical gear shaft adopts an inclined tooth profile, which makes the transmission smoother and is suitable for high-speed and high-load applications.

24 2025-09

24 2025-09 What Are the Advantages of Using Steel Hubless Spur Gears?

In today's competitive industrial landscape, procurement specialists constantly seek components that deliver reliability, efficiency, and cost-effectiveness. Steel Hubless Spur Gears stand out as a prime example, offering a robust solution for high-torque, high-precision applications. Their simple, cylindrical design without a central hub provides exceptional strength-to-weight ratios and facilitates easier installation and maintenance.

22 2025-09

22 2025-09 What are the cost considerations for module steel spur gears?

This is a critical question for procurement professionals aiming to balance quality, performance, and budget in industrial applications. From initial material costs to long-term maintenance expenses, understanding these factors can significantly impact your project's success and operational efficiency.