Gear Rack

At Raydafon Group, we manufacture gear racks designed to deliver precise linear motion and high load capacity for industrial machinery. With decades of expertise in power transmission, our gear racks are engineered to meet the demands of automation, robotics, and heavy-duty equipment. Let us help you optimize your motion control systems with reliability and efficiency.

Product Classification

We categorize our gear racks to streamline your procurement process:

-

By Structure

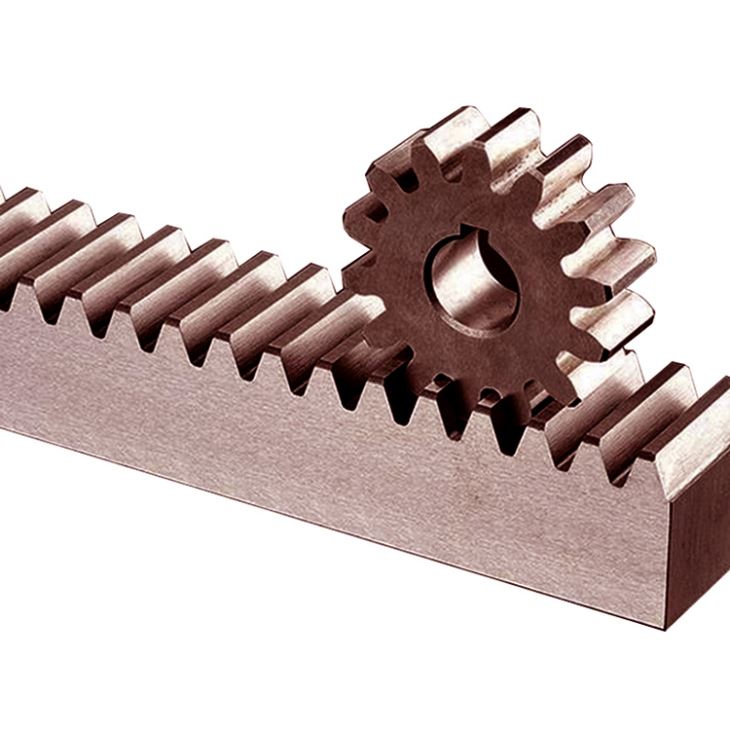

- Straight Tooth Gear Racks: For standard linear motion applications.

- Helical Tooth Gear Racks: Offer smoother, quieter operation at high speeds.

-

By Material

- Steel Alloys: High-strength 42CrMo4 and C45 grades for heavy loads.

- Stainless Steel: Corrosion-resistant options for harsh environments.

- Aluminum: Lightweight solutions for rapid motion systems.

-

By Application

- Industrial Automation: CNC machinery, robotic arms.

- Material Handling: Conveyors, lifts, and shuttle systems.

- Aerospace & Defense: Precision actuators and positioning stages.

Product Introduction

Why choose Raydafon gear racks?

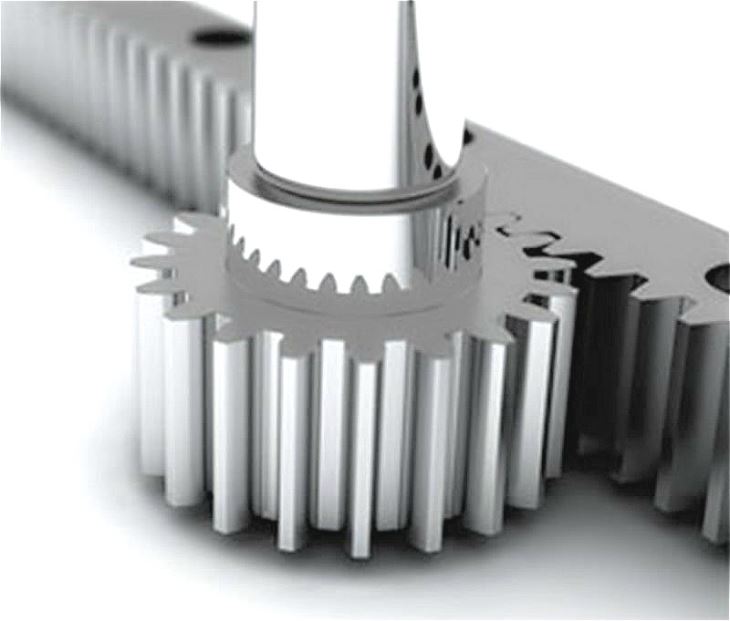

Gear racks are critical components that convert rotational motion into linear motion, often paired with pinion gears. Our designs prioritize precision, durability, and smooth operation, making them ideal for applications requiring exact positioning and heavy load management.

Key Design Principles:

- Precision Engineering: Ground and hardened teeth for minimal backlash.

- Load Distribution: Optimized tooth profiles for even stress distribution.

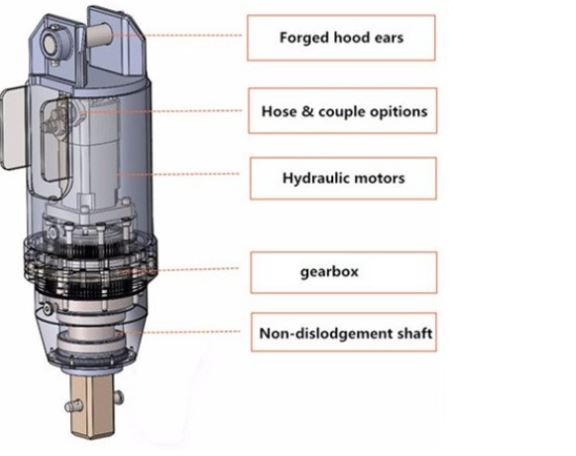

- Interoperability: Compatible with Raydafon pinions, couplings, and motors.

Product Features

1. Material Excellence

- High-Grade Alloys: 42CrMo4 steel for 500%+ nominal load resistance.

- Protective Coatings: Black oxide and anti-corrosion finishes for longevity.

2. Customization Flexibility

- Tailored Specifications: Adjust length, module, and pressure angle to your needs.

- Certified Engineering: Our ISO-certified team designs racks for your exact speed, load, and environmental requirements.

3. Smart Integration

- IoT-Ready Design: Pre-drilled holes for sensors (compatible with Raydafon’s SmartDrive platform).

- Universal Compatibility: Works with third-party motion systems—while outperforming them.

4. Certifications & Standards

- ISO 9001 (Quality Management)

- CE Marking (EU Safety Compliance)

- RoHS Compliance (Environmental Safety)

Product Advantages

1. Motion Precision

- Sub-Micron Accuracy: Ground teeth ensure minimal backlash and vibration.

- High-Speed Performance: Helical designs reduce noise at 3+ m/s velocities.

2. Global Support Network

- 24/7 Engineering Assistance: Our ISO-certified team supports you in 28 countries.

- JIT Delivery: Three regional hubs ensure 3–6 week lead times for bulk orders.

3. Cost Optimization

- Vendor-Managed Inventory (VMI): Reduce upfront costs and stockouts.

- 92% Client Retention: Trusted by Fortune Global 500 companies in automation and aerospace.

Application Areas

| Industry | Use Case | Why Procure Raydafon? |

|---|---|---|

| Automation | CNC machinery, robotic arms | Sub-micron accuracy, 24/7 support |

| Material Handling | Conveyors, lifts, shuttle systems | High load capacity, corrosion-resistant options |

| Aerospace | Precision actuators, positioning stages | Lightweight aluminum, helical tooth designs |

| Defense | Turret systems, missile launchers | Shock-resistant steel, extreme temperature performance |

Frequently Asked Questions (FAQs)

Q1: Can Raydafon manufacture gear racks for custom lengths?

Yes. We produce racks up to 6 meters in length, with precision cutting and finishing.

Q2: What is the minimum order quantity (MOQ) for custom gear racks?

Flexible MOQs start at 10 units, with vendor-managed inventory for bulk buyers.

Q3: How do Raydafon gear racks perform in extreme temperatures?

Cryogenic treatments and heat-resistant coatings enable operation from -40°C to +200°C.

Q4: Do you offer predictive maintenance for gear rack systems?

Yes. SmartDrive IoT monitors tooth wear, alignment, and lubrication in real time.

Q5: Are Raydafon gear racks compatible with third-party pinions?

Yes. Universal designs ensure compatibility while offering 40%+ durability gains over market averages.

Technical Specifications

| Parameter | Details |

|---|---|

| Material | 42CrMo4 steel, C45 steel, stainless steel, aluminum |

| Module Range | 0.5–20 (DP 64–1) |

| Max Length | 6,000mm (customizable) |

| Certifications | ISO 9001, CE, RoHS |

- View as

Greenhouse Window Ventilation Frame Gear Rack Set

Fiberglass Reinforced Nylon Gear Rack With Metal Insert

Metric Gear Rack

Round Gear Racks